While the “sticker shock” of LED light bulbs may prove to be a deterrent to consumers, LEDs will soon be what we use to replace incandescent bulbs. They were slow to take off in the market because the first generation of LED bulbs had a narrow and focused light beam, and the cost was simply too high.

As technology progresses, however, these issues have slowly ceased. Manufacturers have “clustered” LEDs to provide more light, and have mounted them within diffuser lenses which allows light to be spread across a wider area. Advancements in manufacturing technology have also been able to drive the costs of LEDs down to a level where they are now more cost effective than both CFLs and incandescent light bulbs.

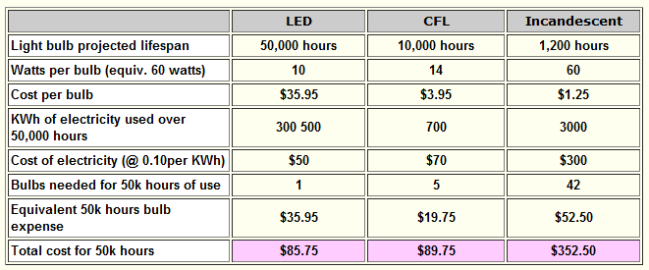

The chart below illustrates the value of LEDs compared to CFLs and incandescents in terms of both energy efficiency and cost-effectiveness.

If you own or manage a business or commercial building and want to see what your savings would be like if you switched to LEDs, we can help. We will provide you with a detailed report showing the costs, savings, and other benefits of a modern lighting system. Assistance will be provided to acquire State, Federal and utility rebates and incentives if you choose to make the switch. Learn more here.

Continuing product development for the safe handling of burned-out fluorescent lamps and compact fluorescent lamps (CFLs) is becoming more important as the use of these bulbs grows. Researchers at the University of Minnesota tested multiple types of packaging meant to contain mercury vapor from broken lamps. The effective package is made up of three layers, with a foil-plastic bag positioned between two cardboard layers, yet it may not protect against mercury vapor levels that can accumulate from broken bulbs inside the package—indicating a need for adsorption.

Recently NUCON International, Inc., a world-wide leader in providing gas, vapor and liquid phase adsorption solutions, tested mercury vapor levels emitted from broken bulbs both inside and outside of the same packaging. Testing results revealed that while outer levels were safe, interior vapor levels could reach over 150 to 300 times the health and safety exposure limits and guidelines set by OSHA’s 8-hour PEL (permissible exposure limit) level of 100 micrograms per cubic meter. However, vapor levels were decreased to a safe concentration when a new, patent-pending adsorbent was added to the flap of the inner cardboard box within the mercury-safe packaging.

The adsorbent technology was recently announced at the Air & Waste Management Association’s Conference & Exhibition, and can effectively capture mercury vapor and reduce vapor levels by nearly 60 percent after only 15 minutes, more than 70 percent within an hour and over 95 percent after 12 hours. This shows the importance of not only focusing on containing mercury vapor, but also capturing it. A small consumer-size recycling bag, available soon, will feature this adsorbent technology and allow people to safely store three to four used lamps at home before taking them to a retailer or municipality that accepts CFLs for recycling.

View a short animated depiction of the adsorption process at http://www.vaporlokproducts.com/capturedemo.

Download a detailed White Paper on this technology at http://www.vaporlokproducts.com/capturewhitepaper.pdf.